WOOD MAKES THE COLLEGE CHAIR

IT ALL STARTS WITH GREAT, LOCAL, OHIO WOODS

Alumni Chairs offers 25 models of college chairs. You may choose our available wooden college chairs, wood captains chairs, or captain’s chairs wooden. Or you may design your own wooden college chair.

Whereas our Classic College Chairs can be made from several species of wood, our Traditional College Chairs, including our wooden captain chairs, are made of a combination of Brown Maple and Cherry and stained in any of several Ohio Certified wood stains. Most purchasers of our captain’s chairs wooden chairs and wood captain chairs choose a finish of Black Lacquer. A wooden captain’s chairs with arms can be customized by selecting arms and/or crown (headrest) in any of several stains: several Cherry stains, Maple, Walnut, and many more. Also, all of our college chairs can be made in any of these stains. All of our Amish captain’s chairs wooden, wood captains chairs, and wooden captain’s chairs with arms are made in Ohio, have Solid Cherry Crowns and solid Cherry Arms.

Building Classic College Chairs and Heritage College Chairs at Alumni Chairs begins with solid American hardwoods including cherry, hickory, walnut, maple, white oak, and beautiful quarter-sawn oak (white oak). Our woods are kiln-dried to ensure durability and resist cracking and shrinkage in extreme climates. We use no endangered woods and materials. Whereas other companies that build wooden captains chairs with arms in inexpensive woods from Asia, our sources of woods are the Amish sawmills of northeastern Ohio, exclusively.

Although Alumni Chairs makes several wood species available, our most popular species for wooden captain’s chairs are Maple and Cherry. Maple trees are abundant throughout the Eastern and Midwestern States and, therefore, more affordable than the other woods which we offer, and, yet, maple is an attractive and excellent hardwood with which to work. In Ohio, we obtain our woods from private old forest and private tree farms. Unless a specific wood is requested, we will normally build our captain’s chairs wooden captain’s chairs from Brown Maple, because it is a hard wood, it displays interesting colors and grains, and its cost is reasonable. If you would prefer another wood, we will accommodate your request and price the chair accordingly. Some woods may require a surcharge to compensate for current market prices at the time of the quote. We encourage you to make an informed, thoughtful choice of style, wood, and finish as your wooden captain’s chairs and other college chairs will likely serve your family well for generations.

Please continue reading about all of the woods that you may choose for your new, college logo wooden chairs from Alumni Chairs.

Cherry

Cherry wood stains well and finishes beautifullly. Cherry ages well and it id often produced in environmentally sustainable forests. Cherry appears in 430 species grown throughout the northern, temperate regions of the world, including eastern United States. Cherry shares the name “fruitwood” with other light-brown woods. Cherry wood is hard, strong, closed grain, light brown to red-brown wood in its heartwood. Cherry is resistant to warping. Its sapwood is a lighter pink. It is easily carved. In New England, Cherry is known as New England Mahogany because of its color, grain, and density. Cherry can be used as structural wood or it can be used as a veneer. (Alumni Chairs does not use veneers ─ only solid wood). The Cherry tree shares the genus Prunus which includes trees and shrubs which include plums, peaches, nectarines, apricots and almonds. The fruit from this genus are commonly called “stone fruit” and are cultivated for both ornamentation and fruit. Cherry wood enables builders to create extremely elegant and desirable furniture. We build the Crowns and Arms of our Amish Traditional Chairs including our wooden captains chairs. We select brown maple and cherry for our wooden Captains Chair. of Solid cherry. No other builder does this. Ask us about Cherry in your next wooden college chair.

Cherry wood stains well and finishes beautifullly. Cherry ages well and it id often produced in environmentally sustainable forests. Cherry appears in 430 species grown throughout the northern, temperate regions of the world, including eastern United States. Cherry shares the name “fruitwood” with other light-brown woods. Cherry wood is hard, strong, closed grain, light brown to red-brown wood in its heartwood. Cherry is resistant to warping. Its sapwood is a lighter pink. It is easily carved. In New England, Cherry is known as New England Mahogany because of its color, grain, and density. Cherry can be used as structural wood or it can be used as a veneer. (Alumni Chairs does not use veneers ─ only solid wood). The Cherry tree shares the genus Prunus which includes trees and shrubs which include plums, peaches, nectarines, apricots and almonds. The fruit from this genus are commonly called “stone fruit” and are cultivated for both ornamentation and fruit. Cherry wood enables builders to create extremely elegant and desirable furniture. We build the Crowns and Arms of our Amish Traditional Chairs including our wooden captains chairs. We select brown maple and cherry for our wooden Captains Chair. of Solid cherry. No other builder does this. Ask us about Cherry in your next wooden college chair.

Hickory

Hickory is extremely heavy and it is a very strong wood. It has a close grain and is generally a light wood. However, some pieces of hickory can display both light and dark grain. Grain patterns vary widely amd display a very distinct appearance. Hickory is popular in rustic furniture. Hickory is employed in applications that require great strength and durability. Hickory wood is very hard, stiff, dense and shock resistant. There are woods that are stronger than Hickory and woods that are harder, but the combination of strength, toughness, hardness and stiffness found in Hickory wood is not found in any other commercial wood. Skis, archers’ bows, other sports equipment, wagon-wheel spokes, drumsticks, and hand tools have long used Hickory as a structural part ─ especially where strength and thinness are required. Decorative Hickory veneers are also commonly used. (Alumni Chairs does not use veneers ─ only solid wood). There are 19 species of Hickory. American Hickory is found mostly in the eastern forests.

Hickory is extremely heavy and it is a very strong wood. It has a close grain and is generally a light wood. However, some pieces of hickory can display both light and dark grain. Grain patterns vary widely amd display a very distinct appearance. Hickory is popular in rustic furniture. Hickory is employed in applications that require great strength and durability. Hickory wood is very hard, stiff, dense and shock resistant. There are woods that are stronger than Hickory and woods that are harder, but the combination of strength, toughness, hardness and stiffness found in Hickory wood is not found in any other commercial wood. Skis, archers’ bows, other sports equipment, wagon-wheel spokes, drumsticks, and hand tools have long used Hickory as a structural part ─ especially where strength and thinness are required. Decorative Hickory veneers are also commonly used. (Alumni Chairs does not use veneers ─ only solid wood). There are 19 species of Hickory. American Hickory is found mostly in the eastern forests.

Walnut

Walnut is dark brown in color. Walnut is a rich, elegant wood, and it is slightly more expensive than other hardwoods. The Walnut tree or Juglans is a plant genus of the family Juglandaceae, the seeds of which are known as walnuts. There are 21 species in the genus ranging from southeast Europe east to Japan, and southeast Canada west to California and south to Argentina. The Walnut tree is closely related to Black Walnut and Hickory trees. Walnut is hard and durable, but not too heavy. Like Cherry, Walnut is an excellent carving wood. It has excellent woodworking qualities, and takes finishes well. Walnut is used in all types of fine cabinet work, especially 18th century reproductions. It is a popular wood for cabinet making. The color of Walnut varies from light to dark brown with a straight grain in the trunk. Walnut stumps are often dug out and used as a source of highly figured veneer.

Walnut is dark brown in color. Walnut is a rich, elegant wood, and it is slightly more expensive than other hardwoods. The Walnut tree or Juglans is a plant genus of the family Juglandaceae, the seeds of which are known as walnuts. There are 21 species in the genus ranging from southeast Europe east to Japan, and southeast Canada west to California and south to Argentina. The Walnut tree is closely related to Black Walnut and Hickory trees. Walnut is hard and durable, but not too heavy. Like Cherry, Walnut is an excellent carving wood. It has excellent woodworking qualities, and takes finishes well. Walnut is used in all types of fine cabinet work, especially 18th century reproductions. It is a popular wood for cabinet making. The color of Walnut varies from light to dark brown with a straight grain in the trunk. Walnut stumps are often dug out and used as a source of highly figured veneer.

White Maple

Also known as Silver Maple, White Maple grows in the Great Lakes Region of the United State and Canada. Hard Rock Maple is excellent for high ‘impact resistant’ applications or in applications which require a uniform light yellow-white color of wood. Northern Maple is 50 percent harder than Red Oak wood. Maple has a strong, uniform grain. Maple often shows a unique, bright luster and texture depending on the angle of light source. Typically, maple has fine grain with straight lines, maple has a high degree of stability. It’s also more affordable than other hardwoods and takes on a cherry look when finished with dark cherry stain.

Also known as Silver Maple, White Maple grows in the Great Lakes Region of the United State and Canada. Hard Rock Maple is excellent for high ‘impact resistant’ applications or in applications which require a uniform light yellow-white color of wood. Northern Maple is 50 percent harder than Red Oak wood. Maple has a strong, uniform grain. Maple often shows a unique, bright luster and texture depending on the angle of light source. Typically, maple has fine grain with straight lines, maple has a high degree of stability. It’s also more affordable than other hardwoods and takes on a cherry look when finished with dark cherry stain.

Brown Maple

Brown Maple is not a distinct specie of maple tree. It is the “heart wood” (wood near the center of a tree) of various soft maple trees. Brown Maple ranges in colors from light beige to medium brown. The furniture industry has established Brown Maple as a distinct wood type but purely for marketing considerations. What is known as Brown Maple is actually Soft Maple that has been renamed as “brown”. Soft Maple is usually mischaracterized because of the term “soft” ─ perhaps because it is less hard than Sugar Maples (Hard Maples). Soft Maple is not actually soft but enjoys a hard rating similar to that of Cherry. Red maple has a density similar to that of Black Walnut but is a bit more dense than Cherry. Brown Maple is often used in lieu of Cherry. We select brown maple and cherry for our wooden captains chair. Brown maple is our most popular wood for our Affinity Classic Alumni Chairs. Although the market prices fluctuate, the cost of Brown Maple is often less than that of Cherry.

Brown Maple is not a distinct specie of maple tree. It is the “heart wood” (wood near the center of a tree) of various soft maple trees. Brown Maple ranges in colors from light beige to medium brown. The furniture industry has established Brown Maple as a distinct wood type but purely for marketing considerations. What is known as Brown Maple is actually Soft Maple that has been renamed as “brown”. Soft Maple is usually mischaracterized because of the term “soft” ─ perhaps because it is less hard than Sugar Maples (Hard Maples). Soft Maple is not actually soft but enjoys a hard rating similar to that of Cherry. Red maple has a density similar to that of Black Walnut but is a bit more dense than Cherry. Brown Maple is often used in lieu of Cherry. We select brown maple and cherry for our wooden captains chair. Brown maple is our most popular wood for our Affinity Classic Alumni Chairs. Although the market prices fluctuate, the cost of Brown Maple is often less than that of Cherry.

Maple is the most popular wood for building our wooden college chairs. Maple trees are abundant throughout the east and midwest and, therefore, more affordable than the other woods which we offer,..and, yet, maple is an attractive and excellent hardwood with which to work. This is why most wooden college chairs are constructed from Maple.

Red Oak

Oak is the most popular wood used to build American and English country designs. Red oak is a classic choice for furniture, that is popular because of its affordability. Red Oak is strong, it is easy to work, and it is generally of a reddish-brown color. The of red oak is too large and course for some furniture buyers. Although there are many species of oak grown in North America, for the purpose of furniture making, oak is usually categorized as either of two varieties: Red Oak and White Oak.

White Oak

Although there are many species of oak grown in North America, for the purpose of furniture making, oak is usually categorized as either of two varieties: Red Oak and White Oak. White Oak is a dense, strong hardwood in a light color with a course texture and uniquely prominent grain. Oak boasts obvious medullary rays which can be seen as “flakes” or “fleks” in quarter-sawn oak lumber. It is also used for Gothic and William & Mary reproductions, as well as many transitional and contemporary pieces. Also strong and easy to work with, this wood type has a golden-brown hue. It has a finer grain than red oak and comes quarter-sawn, which means it is cut at an angle for a grainy appearance. White Oak is the preferred oak specie for the Quarter Sawn Oak from which we build our Affinity Mission Rocking Chair and, as an option, our Affinity Mission Chair.

Although there are many species of oak grown in North America, for the purpose of furniture making, oak is usually categorized as either of two varieties: Red Oak and White Oak. White Oak is a dense, strong hardwood in a light color with a course texture and uniquely prominent grain. Oak boasts obvious medullary rays which can be seen as “flakes” or “fleks” in quarter-sawn oak lumber. It is also used for Gothic and William & Mary reproductions, as well as many transitional and contemporary pieces. Also strong and easy to work with, this wood type has a golden-brown hue. It has a finer grain than red oak and comes quarter-sawn, which means it is cut at an angle for a grainy appearance. White Oak is the preferred oak specie for the Quarter Sawn Oak from which we build our Affinity Mission Rocking Chair and, as an option, our Affinity Mission Chair.

Quarter-sawn Oak

Clients love our quarter-sawn oak chairs. Quarter sawing is method of sawing oak so the cut is made parallel to the wood’s medullary rays instead of across. This cut yields a limited quantity of top grade boards featuring ray flake, and it binds the perpendicular fibers together, giving the oak its amazing strength. Quarter sawn White Oak is much less likely to crack or warp than when it is “flat sawn”. White Oak is similar to red oak but slightly harder, and, when “quarter sawn”, it provides more “ray flake or fleks”, the distinctive striping which is seen in many antique Oak pieces. Quarter sawn Oak has been popular in American architecture in addition to Mission and Craftsman furniture styles since the late nineteenth century. Read about Quarter sawn Lumber, below. See excellent examples of Quarter sawn Oak – our Affinity Mission Rocking Chair and, as an option, our Affinity Mission Chair.

Clients love our quarter-sawn oak chairs. Quarter sawing is method of sawing oak so the cut is made parallel to the wood’s medullary rays instead of across. This cut yields a limited quantity of top grade boards featuring ray flake, and it binds the perpendicular fibers together, giving the oak its amazing strength. Quarter sawn White Oak is much less likely to crack or warp than when it is “flat sawn”. White Oak is similar to red oak but slightly harder, and, when “quarter sawn”, it provides more “ray flake or fleks”, the distinctive striping which is seen in many antique Oak pieces. Quarter sawn Oak has been popular in American architecture in addition to Mission and Craftsman furniture styles since the late nineteenth century. Read about Quarter sawn Lumber, below. See excellent examples of Quarter sawn Oak – our Affinity Mission Rocking Chair and, as an option, our Affinity Mission Chair.

Traditional-cut Lumber

When boards are cut from a log they are usually rip cut along the length (axis) of the log. This can be done in three ways: plain-sawing (most common, also known as flat-sawn, bastard-sawn, through and through, and tangent-sawn), quarter sawing (less common), or rift sawing (rare).

In flat-sawing, the log is passed through the blade cutting off plank after plank without changing the orientation of the blade or log. The resulting planks have different annual ring orientations when viewed from the end. The relative angle that form the rings and the surface go from almost zero degrees in the external planks to almost ninety degrees at the core of the log.

Quarter-sawn Lumber

Quarter sawing is a type of cut in the rip-sawing of logs into lumber. The resulting lumber is called quarter sawn, quarter sawn, quartered, and radially-sawn. There is widespread confusion between the terms quarter sawn and rift-sawn with both words defined with opposite meanings and as synonyms. Quarter sawn boards have greater stability of form and size with less cupping, shrinkage across the width, shake and splitting, and other good qualities. In some woods, the grain produces a decorative effect such as oak which shows a prominent ray fleck, and Sapele (or Sapelli, an redish-brown African hardwood often used for flooring) is likely to produce a ribbon figure.

Quarter sawing is a type of cut in the rip-sawing of logs into lumber. The resulting lumber is called quarter sawn, quarter sawn, quartered, and radially-sawn. There is widespread confusion between the terms quarter sawn and rift-sawn with both words defined with opposite meanings and as synonyms. Quarter sawn boards have greater stability of form and size with less cupping, shrinkage across the width, shake and splitting, and other good qualities. In some woods, the grain produces a decorative effect such as oak which shows a prominent ray fleck, and Sapele (or Sapelli, an redish-brown African hardwood often used for flooring) is likely to produce a ribbon figure.

Quarter sawing gets its name from the fact that the log is first quartered lengthwise, resulting in wedges with a right angle ending at approximately the center of the original log. Each quarter is then cut separately by tipping it up on its point and sawing boards successively along the axis. That results in boards with the annual rings mostly perpendicular to the faces. Quarter sawing yields boards with straight striped grain lines, greater stability than flat-sawn wood, and a distinctive ray and fleck figure. It also yields narrower boards, because the log is first quartered, which is more wasteful. (source:https://en.wikipedia.org/wiki/Quarter_sawing) More about quarter-sawn wood.

The construction of Amish chairs is only as effective and successful as the construction techniques applied during the construction of the those same chairs. Amish chairs and furniture will achieve great longevity and structural integrity over time due to the drying process, preventIng decomposition in indoor environments. Wood used in chairs of Alumni Chairs LLC is kiln-dried for strong, durable wood to minimize warping and splitting to enhance the durability and longevity of the chairs.

The most sound, durable furniture consist of northern hardwood construction. Hardwoods from the colder, northern climates offer greater density which means stronger wood for furniture pieces than wood from warmer regions. Examples of northern hardwoods Cherry, Hickory, Maple, Walnut, and Oak. There is no way to know the species or the source of the wood in a factory chair. Because most mass-produced chairs are finished in black paint, it’s anyone’s guess. When one buys an Amish chair or a chair from a custom shop, one can have a high degree of confidence in the choice of wood by the builder.

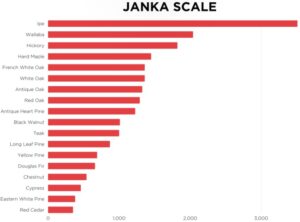

HARDNESS

The Janka Wood Hardness Scale refers to a range of numbers that determine how dense a type of wood is and how resistant to dents, dings, and wear that a type of wood will be once installed.

The Janka wood hardness rating scale is determined by the Janka hardness test. The Janka hardness test measures the resistance of a sample of wood to denting and wear. It measures the force required to embed an 11.28 millimeters (0.444 in) diameter steel ball halfway into a sample of wood. This method leaves a hemispherical indentation with an area of 100 mm2. (Wikipedia, n.d.) With the Janka wood hardness scale in mind, the higher the number, the more resistant the wood is to denting and wear. For reference, when comparing two types of wood like Hickory and Chestnut, Hickory has a Janka wood hardness rating of 1820 while Chestnut has a rating of 540, therefore, from this scenario, we can conclude that Hickory is the more resistant wood. The Janka rating is also a good indication of how hard the wood will be to saw or nail. Sample ratings: Red Oak (1290), White Oak (1360), Hard Maple (1450), and Black Walnut (1010). More about the Janka Scale.

What is the difference between hardwood and softwood?

WOOD THAT IS OF CONCERN

One manufacturer of college chairs, YourCustomChair.com builds its chairs of rubberwood from the rubber tree or para tree. That company calls this wood “Malaysian Oak”. It is not oak. Imported rubberwood is often marketed as a sustainable and eco-friendly alternative to traditional hardwoods. While this type of wood is economical, it is important to know more about this species of wood to determine if a purchase of rubberwood furniture is right for you.

For more information about wooden university chairs, wooden captain chairs, wood captain chairs, and wood captains chairs, college wooden logo chairs, wooden alumni chairs, wooden college chairs, quarter sawn oak chairs, or quarter sawn white oak, phone Alumni Chairs at 866.748.2230.